Introduction

PU seals are crucial for many industries, offering durability and performance. Have you ever wondered how these seals are made? In this article, we’ll dive into the process behind creating high-performance polyurethane seals.

You’ll learn how advanced manufacturing techniques, including the use of CNC machines, play a key role in producing these seals. Discover the science behind polyurethane, its advantages, and why CNC machining is integral to ensuring precision and reliability.

Understanding the Basics of PU Seals

What is Polyurethane?

Polyurethane is a polymer material composed of polyols, isocyanates, and chain extenders. Its ability to be both rigid and flexible makes it an ideal candidate for use in sealing components. PU’s unique properties allow it to be tailored for various applications, from high-strength seals to flexible, abrasion-resistant materials used in hydraulic cylinders.

Why Choose PU Over Other Seal Materials?

Compared to rubber and PTFE, PU seals offer numerous advantages. Rubber seals may lose their resilience over time, while PTFE, although chemically resistant, lacks the flexibility and toughness of PU. PU offers the best of both worlds—excellent abrasion resistance, high tensile strength, and lower wear rates, even in extreme conditions.

The PU Seal Manufacturing Process

The One-Step Process for PU Seal Creation

The simplest way to create polyurethane seals is through a one-step process. In this method, polyols and isocyanates are mixed to form a random copolymer, which is then processed into the desired shape. This process creates a highly flexible and durable seal with great resistance to wear and chemical damage.

The Two-Step Process for Enhanced Consistency

A more advanced two-step process involves creating a pre-polymer first and then combining it with a chain extender. This results in a block copolymer with improved material consistency. The two-step process enhances the strength, flexibility, and durability of the final PU seal, making it ideal for demanding applications.

Manufacturing PU Seals Using CNC Technology

How CNC Machines Are Used in PU Seal Production

Computer Numerical Control (CNC) machines are pivotal in the production of high-quality PU seals. CNC lathes are programmed to precisely cut and shape polyurethane materials into custom seal profiles. This process ensures that seals meet exact specifications, maintaining tight tolerances and consistent performance.

Advantages of Using CNC for PU Seal Manufacturing

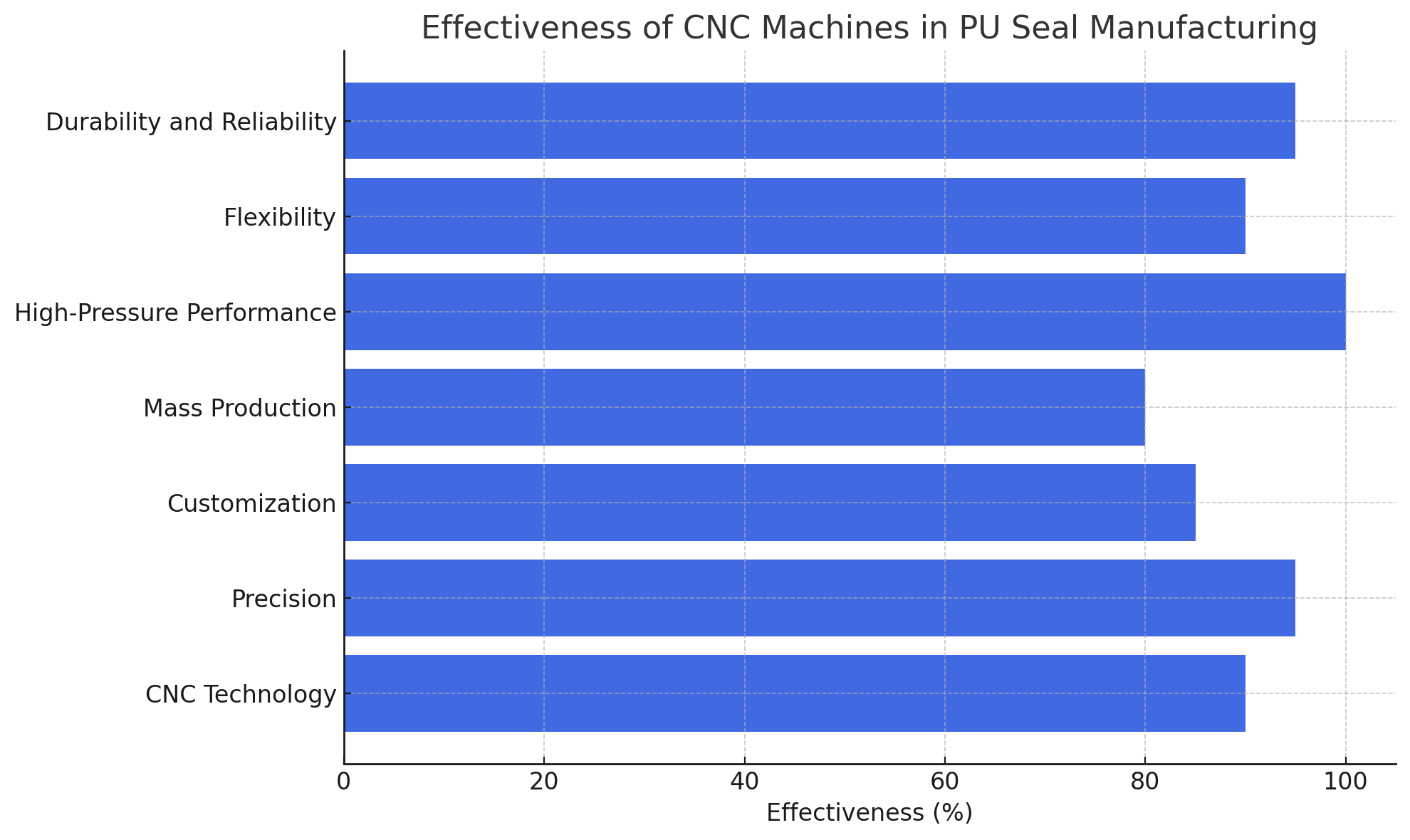

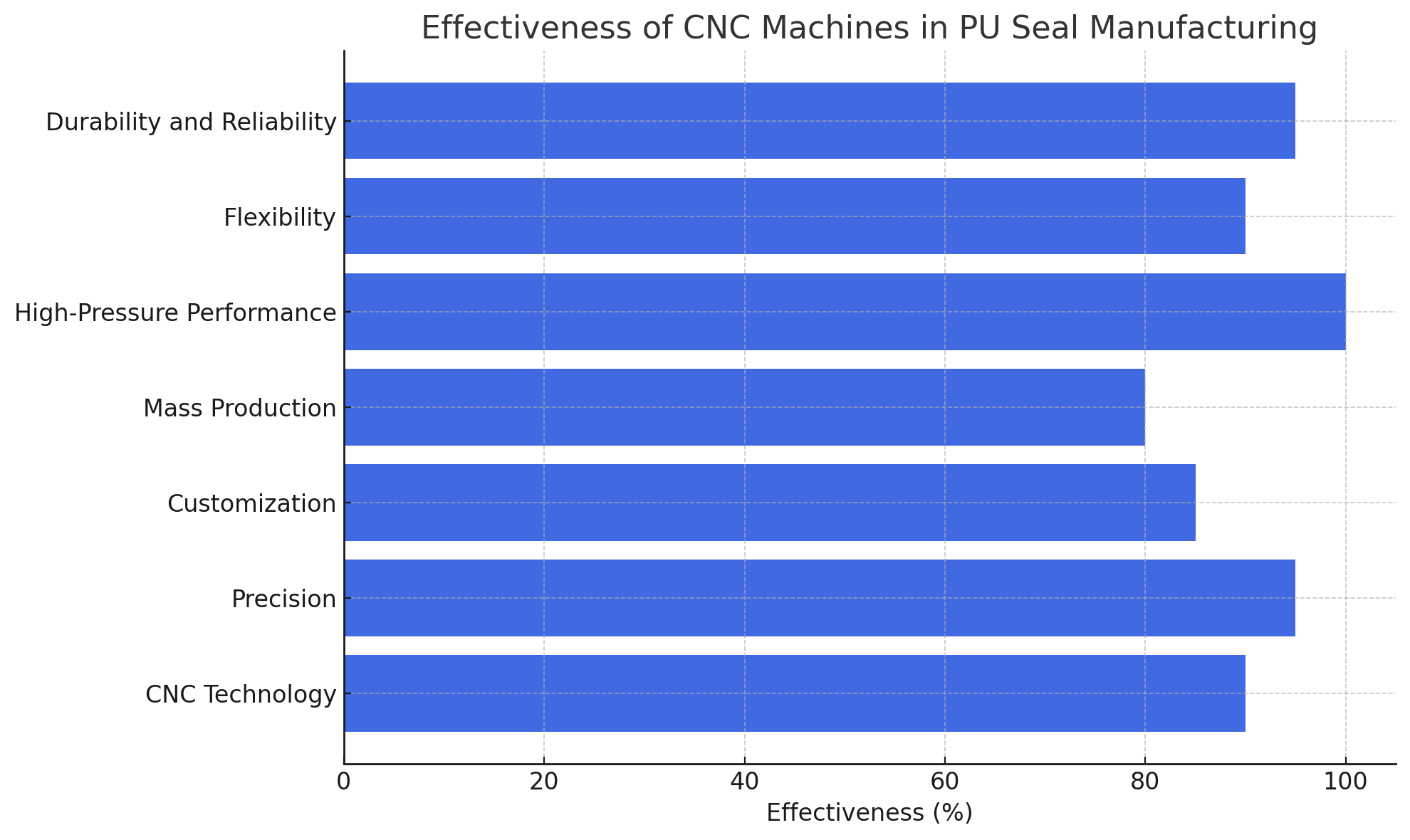

CNC technology provides numerous advantages in the manufacture of PU seals:

● Precision: CNC machines can create intricate seal designs with high precision, reducing errors and ensuring a perfect fit.

● Flexibility: CNC machining can accommodate a variety of materials and is suitable for both small and large production runs.

● Repeatability: Once programmed, CNC machines produce consistent seals with minimal human intervention, enhancing productivity and quality.

How CNC Technology Improves PU Seal Performance

Using CNC machines in the production of PU seals ensures uniformity and precision, which is crucial for high-pressure applications. These seals maintain their integrity and performance even under harsh conditions, providing longer service life and reducing maintenance costs.

Aspect | Details |

CNC Technology | Used for precise, customized production of PU seals. |

Precision | CNC machines ensure high precision in cutting PU material into seal shapes. |

Customization | Allows for the production of custom seal sizes and profiles. |

Mass Production | CNC machines enable both small batch and large-scale production of seals. |

High-Pressure Performance | CNC-manufactured PU seals are optimal for high-pressure applications. |

Flexibility | CNC machining offers flexibility in material selection and design. |

Durability and Reliability | Seals produced with CNC machines have superior durability and reliability. |

Types of PU Seals and Their Applications

Common Types of PU Seals

There are several types of PU seals, each designed for different applications:

● Piston Seals: Used in hydraulic cylinders to prevent fluid leakage around the piston.

● Rod Seals: Seal the rod in hydraulic systems, ensuring no fluid escapes during movement.

● Wiper Seals: Prevent dirt and contaminants from entering the system, thereby protecting other seals and components.

● Static Seals: Used in applications where no movement occurs, sealing gaps between stationary parts.

High-Pressure Applications for PU Seals

PU seals are particularly suited for high-pressure applications, such as those found in:

● Oil & Gas: PU seals can withstand high-pressure environments in drilling equipment and subsea operations.

● Automotive: PU seals are used in engine components to handle both pressure and heat.

● Aerospace: Critical sealing applications in hydraulic systems and fuel lines, where performance and reliability are paramount.

Why PU Seals Are Effective in Harsh Environments

Temperature and Chemical Resistance of PU Seals

Polyurethane seals perform exceptionally well in extreme temperature conditions, ranging from -35°C to +130°C, with specialized grades handling temperatures as low as -50°C and as high as 150°C. Their chemical resistance also makes them suitable for applications involving oils, fuels, and various harsh chemicals.

Durability and Wear Resistance of PU Seals

Polyurethane is highly resistant to abrasion and wear, outlasting rubber seals by up to four times in many cases. This durability is crucial in heavy-duty machinery, where seals are exposed to constant friction, pressure, and contaminants. Additionally, PU seals have excellent tear and tensile strength, which makes them ideal for high-load applications.

The Future of PU Seals and Manufacturing Advancements

Innovation in PU Seal Materials

As technology advances, so does the formulation of polyurethane. New blends and additives enhance the material's resistance to temperature fluctuations, chemicals, and wear. This ongoing innovation expands the range of applications for PU seals, ensuring they remain competitive with alternative materials like PTFE and rubber.

The Role of CNC Technology in PU Seal Advancements

CNC technology is constantly evolving, allowing for even more precise and customized PU seals. Automated systems are making it easier to produce seals with complex geometries and higher performance standards. In the future, automation and AI may play an even bigger role in optimizing the manufacturing process, leading to faster production times and better-performing seals.

Conclusion

Polyurethane seals are crafted through chemical innovation and precision machining. CNC technology ensures they meet exact specifications, offering high performance in harsh environments. When choosing PU seals, consider the system's pressure, temperature, and fluid compatibility. Customized CNC-manufactured seals provide superior reliability and efficiency. BETA's CNC seal machines offer exceptional precision, ensuring durable seals that perform well in demanding applications.

FAQ

Q: What are PU seals made of?

A: PU seals are made from polyurethane, a versatile polymer known for its durability, flexibility, and resistance to abrasion. CNC machining is often used to shape these seals for precise applications.

Q: How are PU seals manufactured using CNC machines?

A: PU seals are produced using CNC machines to precisely cut and shape the material. The CNC technology ensures accurate seal profiles, enhancing performance under high-pressure conditions.

Q: Why are CNC machines used in PU seal production?

A: CNC machines allow for high precision, customization, and repeatability in producing PU seals. This ensures the seals meet exact specifications for demanding industrial applications.

Q: What are the benefits of using PU seals over rubber or PTFE?

A: PU seals offer superior abrasion resistance, lower friction, and higher tensile strength compared to rubber and PTFE, making them ideal for high-pressure environments.

Q: Can CNC technology improve PU seal performance?

A: Yes, CNC technology enhances PU seal performance by providing customization and precise machining, which ensures the seals perform reliably in harsh conditions.