Introduction

CNC machines have revolutionized manufacturing by offering precision and automation. But how exactly do they work in seal production?

In this article, we’ll explore how a seal CNC machine is used to create high-precision seals for various industries. You’ll learn about the role of CNC machines in seal-making, their benefits, and the challenges they address.

What is a CNC Machine?

A CNC machine is a computer-controlled system that uses software to guide machinery tools, such as lathes, mills, and routers, through automated processes. These machines can create parts with exact dimensions by reading and executing a set of instructions, known as G-code. For seal-making, CNC machines are programmed to shape raw materials like rubber, elastomers, or plastics into seals with specific profiles.

The Role of CNC Machines in Manufacturing Seals

CNC machines excel at producing high-precision seals, which is critical in fields like automotive and aerospace. The ability to replicate complex shapes and profiles at scale ensures that seals function effectively in machinery, preventing issues like leakage and wear. CNC technology also allows for fast prototyping and small-scale production, which is crucial for industries needing custom or short-run seals.

How Seal-Making CNC Machines Differ from General CNC Machines

Seal-making CNC machines are specifically designed to handle the unique challenges associated with producing seals. These machines often feature specialized tooling and software that focus on rotary and linear movements. This is important for machining seals, as they typically require a combination of turning and precision cutting to create accurate profiles.

The Seal-Making Process Using CNC Machines

Step 1: Design and CAD Modeling for Seals

Before a seal can be produced, it must be carefully designed. This process begins with creating a 3D model of the seal using Computer-Aided Design (CAD) software. These models are essential as they provide the exact specifications for the CNC machine. In seal-making, CAD software is especially useful because it allows manufacturers to visualize and modify intricate seal profiles before production begins.

Step 2: G-Code Generation for CNC Machining

Once the design is complete, it is converted into a machine-readable code known as G-code. G-code directs the CNC machine on how to move along various axes, controlling the speed and direction of the cutting tools. This code is essential for translating the seal’s design into physical reality. CAM (Computer-Aided Manufacturing) software often plays a crucial role in generating this G-code, optimizing the tool paths for maximum precision and efficiency.

Step 3: Material Selection and Preparation

Selecting the right material for seals is crucial to their performance. CNC machines can work with a variety of materials, including rubber, PTFE, elastomers, and specialized plastics. The material must be chosen based on the seal’s intended use—factors like temperature, pressure, and chemical resistance will all play a role in determining the best material. After selecting the material, it must be prepared for machining, ensuring that it is securely fixed to the CNC machine.

CNC Machines in Action: How Seal-Making Works

Setting Up the CNC Machine

Once the material is selected and the G-code is ready, the CNC machine is prepared for the production process. This involves calibrating the machine to ensure that it operates within the correct parameters. The machine must also be loaded with the appropriate tools for cutting and shaping the seal. This setup is crucial for ensuring the accuracy of the machining process.

The Machining Process: From Raw Material to Finished Seal

During machining, the CNC machine reads the G-code and uses it to guide cutting tools that shape the material into the desired seal profile. The process typically involves turning the raw material while a cutting tool is moved along various axes to trim and shape it. CNC machines can also use various techniques, such as milling or grinding, to achieve the fine tolerances required for high-performance seals.

Quality Control During the CNC Machining Process

Once the seal is formed, it undergoes strict quality control procedures. This step is critical to ensure that the seal meets the required specifications. Quality control may involve measuring the seal against its CAD model to check for accuracy, inspecting for surface defects, and ensuring that the seal functions as intended in its application.

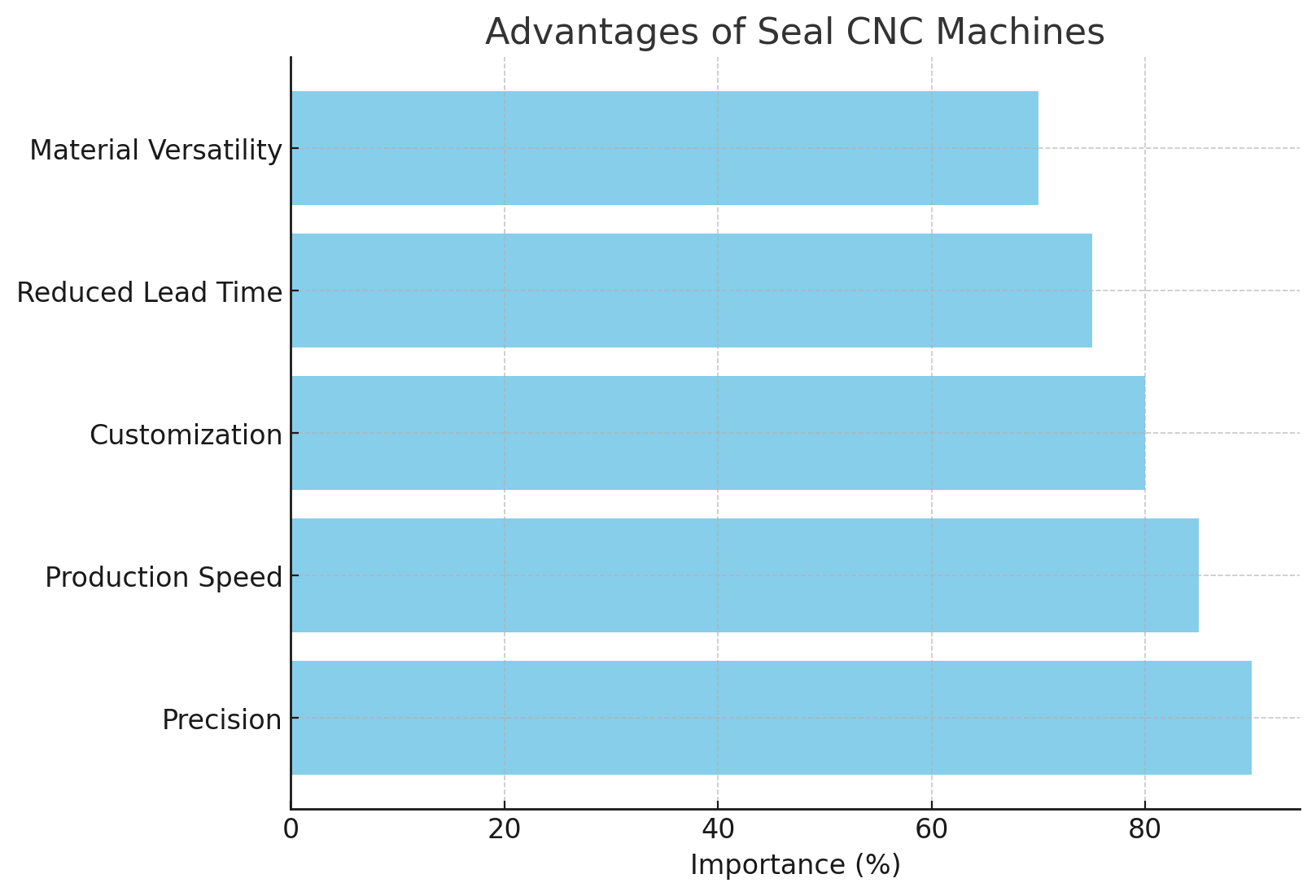

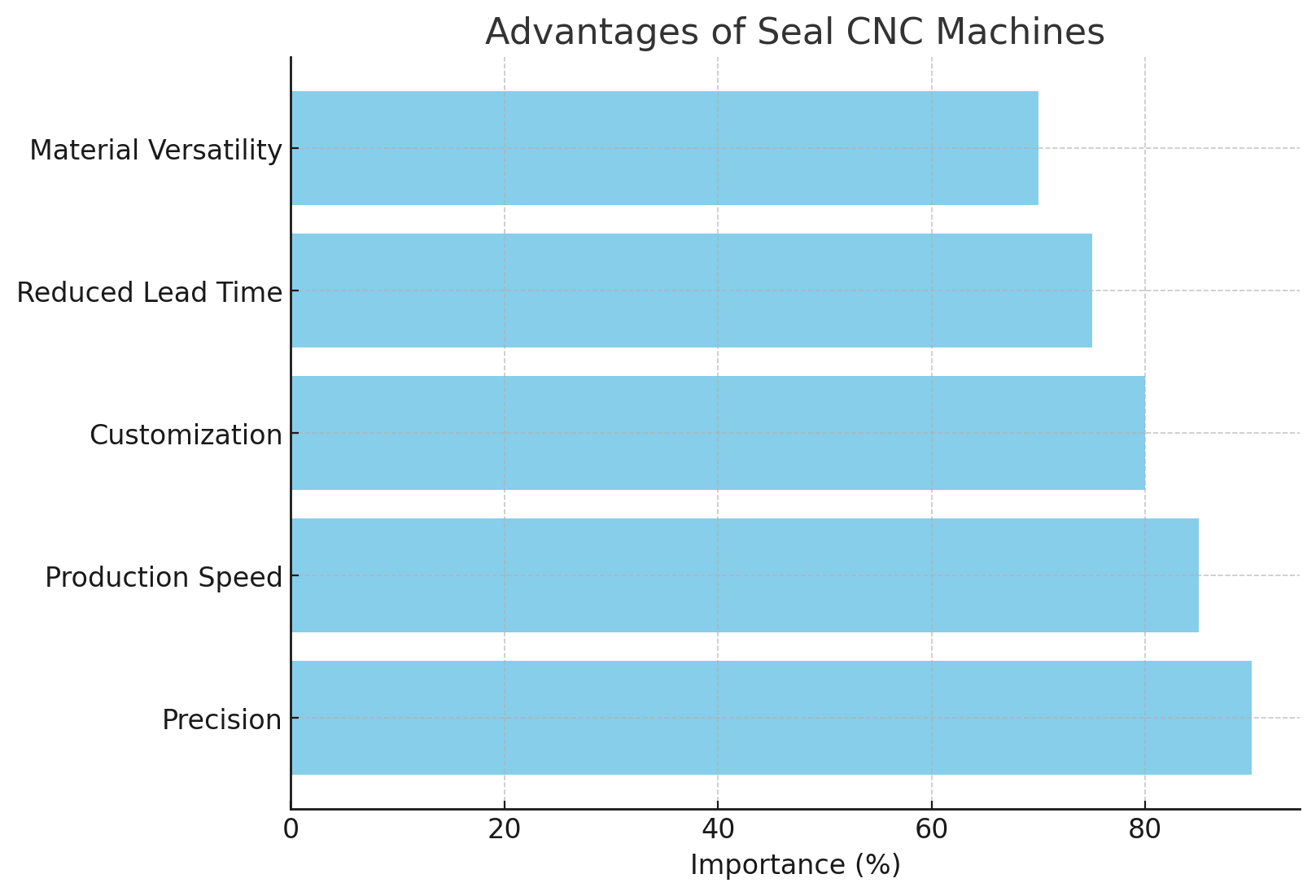

The Advantages of Using CNC Machines for Seal Production

Increased Precision and Accuracy

CNC machines provide unparalleled precision in seal manufacturing. By using pre-programmed G-code, CNC machines can create seals with minimal human intervention, ensuring that each piece is identical and meets stringent specifications. This level of accuracy is particularly important for seals, as even small deviations can lead to leaks or failure in high-pressure systems.

Faster Production and Reduced Lead Times

CNC technology significantly speeds up the production process. Since the machines are automated, production times are drastically reduced compared to manual machining. This efficiency is especially beneficial for manufacturers who need to produce seals quickly for urgent orders or smaller batch runs.

Customization and Flexibility for Complex Designs

CNC machines offer incredible flexibility, allowing manufacturers to create highly customized seals for a range of industries. Whether it's a complex profile or a special material, CNC machines can accommodate intricate designs that would be difficult to achieve with traditional methods. This ability to produce bespoke seals makes CNC technology ideal for industries that require specialized solutions.

Aspect | Details |

What is a Seal CNC Machine? | A computer-controlled machine that shapes materials into seals with high precision and customization. |

Key Materials | Rubber, PTFE, elastomers, plastics. |

Process | The CNC machine uses CAD models to create seals by cutting, shaping, and finishing materials. |

Main Advantages | Increased precision, fast production, customizable seal designs, reduced lead times. |

Applications | Used in industries such as automotive, aerospace, hydraulics, and medical for high-performance seals. |

Future Trends | Advancements in multi-axis machines, AI integration, faster processing speeds, and new materials. |

Common Applications of CNC-Made Seals

Hydraulic and Pneumatic Systems

CNC-machined seals are essential in hydraulic and pneumatic systems, where preventing leaks is critical. Seals in these systems must be durable, resistant to pressure, and capable of maintaining tight tolerances over time. CNC machines ensure that these seals are produced with the precision needed to ensure system efficiency.

Automotive and Aerospace Industries

In the automotive and aerospace sectors, CNC-machined seals are used to prevent fluid leakage and ensure the safe operation of critical components. These seals are typically required to withstand high pressures and extreme temperatures, making CNC machines essential for producing seals that meet these demanding specifications.

Medical and Pharmaceutical Applications

The medical and pharmaceutical industries also rely on CNC-machined seals. These seals often need to meet stringent cleanliness and performance standards. CNC machines allow for the creation of seals that are both precise and safe for use in medical devices, pumps, and other sensitive equipment.

Challenges in Seal-Making with CNC Machines

Material Constraints and Tooling Challenges

Working with different materials presents challenges for CNC machines. For example, hard materials like metals may require specialized tools, while softer materials like rubber can cause tool wear. The material’s properties—such as hardness and elasticity—must be taken into account when selecting the right tooling and machining parameters.

Maintenance and Calibration of CNC Machines

To maintain accuracy, CNC machines require regular maintenance and calibration. Over time, wear and tear on parts like the cutting tools or mechanical components can affect the machine's performance. Regular checks and recalibration ensure that the machines continue to produce high-quality seals.

Balancing Speed and Quality

One of the main challenges in seal-making is balancing speed with the need for high-quality results. While CNC machines are fast, ensuring that each seal meets quality standards requires careful monitoring of the process. Too much focus on speed can lead to mistakes, while prioritizing quality too much can increase lead times. Striking the right balance is essential for meeting both customer demands and quality expectations.

Conclusion

CNC technology has transformed seal-making, offering unmatched precision, efficiency, and customization. These machines enable fast production cycles and highly accurate seals for critical applications in industries like hydraulics, automotive, and healthcare. Looking ahead, CNC machines will continue to evolve with advancements in multi-axis capabilities, faster processing speeds, and AI integration. Companies like BETA are leading the way with products designed to provide high-quality, efficient solutions for seal production, delivering long-term value to industries worldwide.

FAQ

Q: What is a seal CNC machine and how does it work?

A: A seal CNC machine uses computer-controlled systems to precisely cut and shape materials into seals. It automates the manufacturing process, ensuring high accuracy and custom designs for sealing applications.

Q: How does a seal-making CNC machine create custom seals?

A: A seal-making CNC machine reads digital designs from CAD models and converts them into machine instructions. The machine then shapes materials like rubber or elastomers into custom seals with high precision.

Q: Why are CNC machines important for seal production?

A: CNC machines are crucial for seal production because they offer precise control over complex designs, allowing manufacturers to create high-quality, reliable seals for various applications.

Q: What types of materials can a seal CNC machine work with?

A: A seal CNC machine can work with materials like rubber, PTFE, elastomers, and plastics, ensuring flexibility for different sealing applications.

Q: How does a CNC machine improve seal manufacturing efficiency?

A: The seal CNC machine improves efficiency by automating the production process, reducing lead times, and increasing accuracy in the final seal product.