Introduction

Selecting a reliable CNC machine supplier is crucial for ensuring high-quality seal production. The right supplier can significantly affect your product quality, cost-efficiency, and operational performance.

In this guide, we’ll explore the key factors to consider when choosing a seal CNC machine supplier. You’ll learn what to look for in terms of expertise, equipment, reputation, and support to make an informed decision.

Key Factors to Consider in Choosing a Seal CNC Machine Supplier

Evaluate the Supplier’s Expertise in Seal CNC Machines

When choosing a seal CNC machine supplier, expertise is one of the most critical factors. A supplier with extensive experience in seal production will understand the nuances of different seal types, the specific demands of CNC machining, and how to meet custom requirements.

Why It Matters:

● Experience with seal CNC machines enables the supplier to address challenges and improve product outcomes, particularly when dealing with specialized seals.

● An experienced supplier will know how to adjust machine settings and tooling to ensure high precision in seal production.

Assess Product Quality and Precision

Precision is paramount in seal manufacturing, especially when seals are used in high-pressure applications. The CNC machine supplier you choose should have the ability to produce seals with tight tolerances and consistent quality across different production runs.

Why It Matters:

● High precision in seal production ensures that the seals function effectively in hydraulic, pneumatic, or industrial systems without leaks or failures.

● Seal CNC machines must be able to produce seals that meet stringent performance requirements in terms of material properties and geometries.

Review the Supplier’s Equipment and Technology

Modern and advanced CNC machines can make a significant difference in the quality and efficiency of seal production. Look for a supplier that uses up-to-date seal making CNC machines that integrate the latest technology for enhanced performance.

Why It Matters:

● The latest machines offer better precision, faster production speeds, and increased flexibility in terms of seal design and material options.

● A supplier with advanced technology is more likely to provide customized solutions for unique seal requirements.

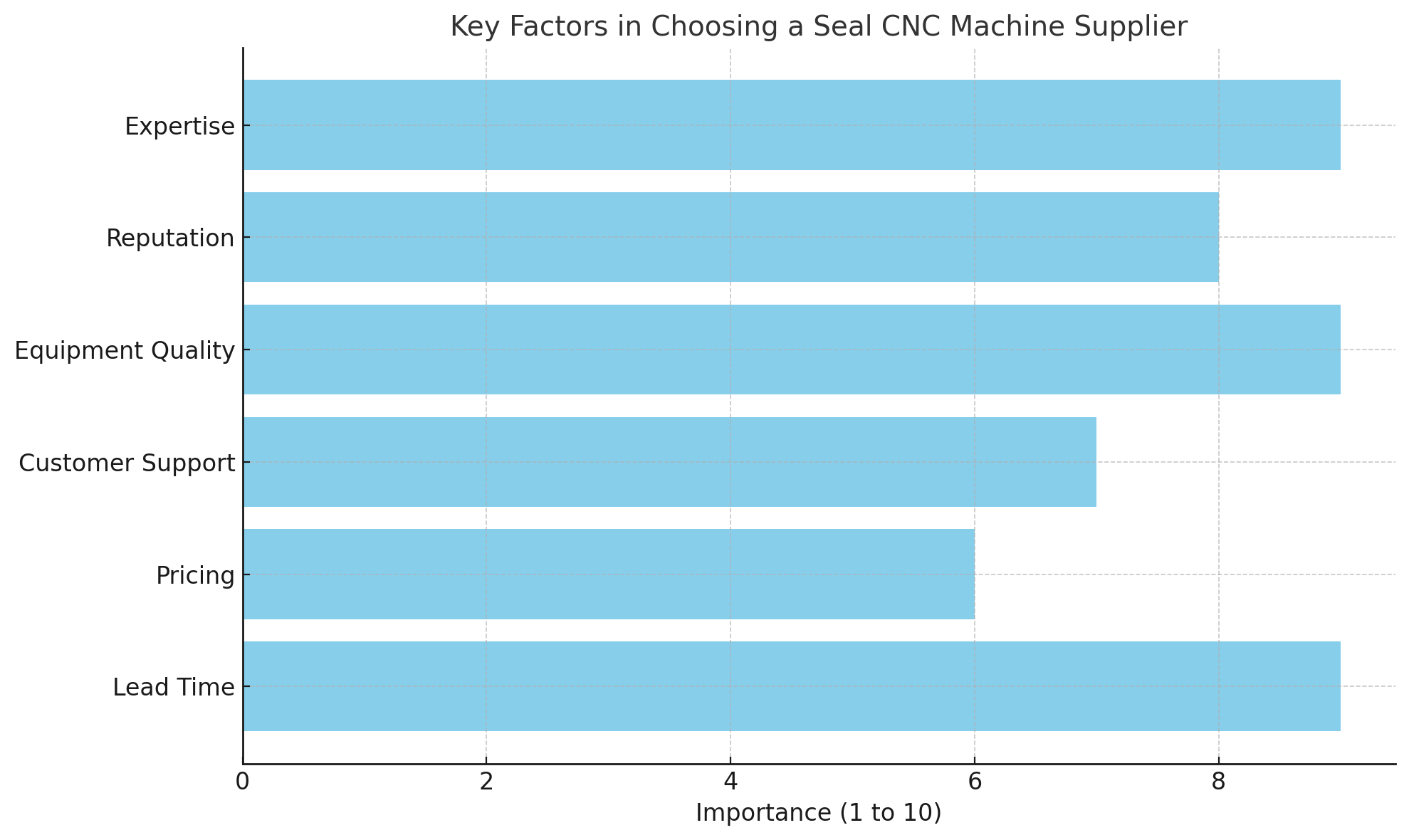

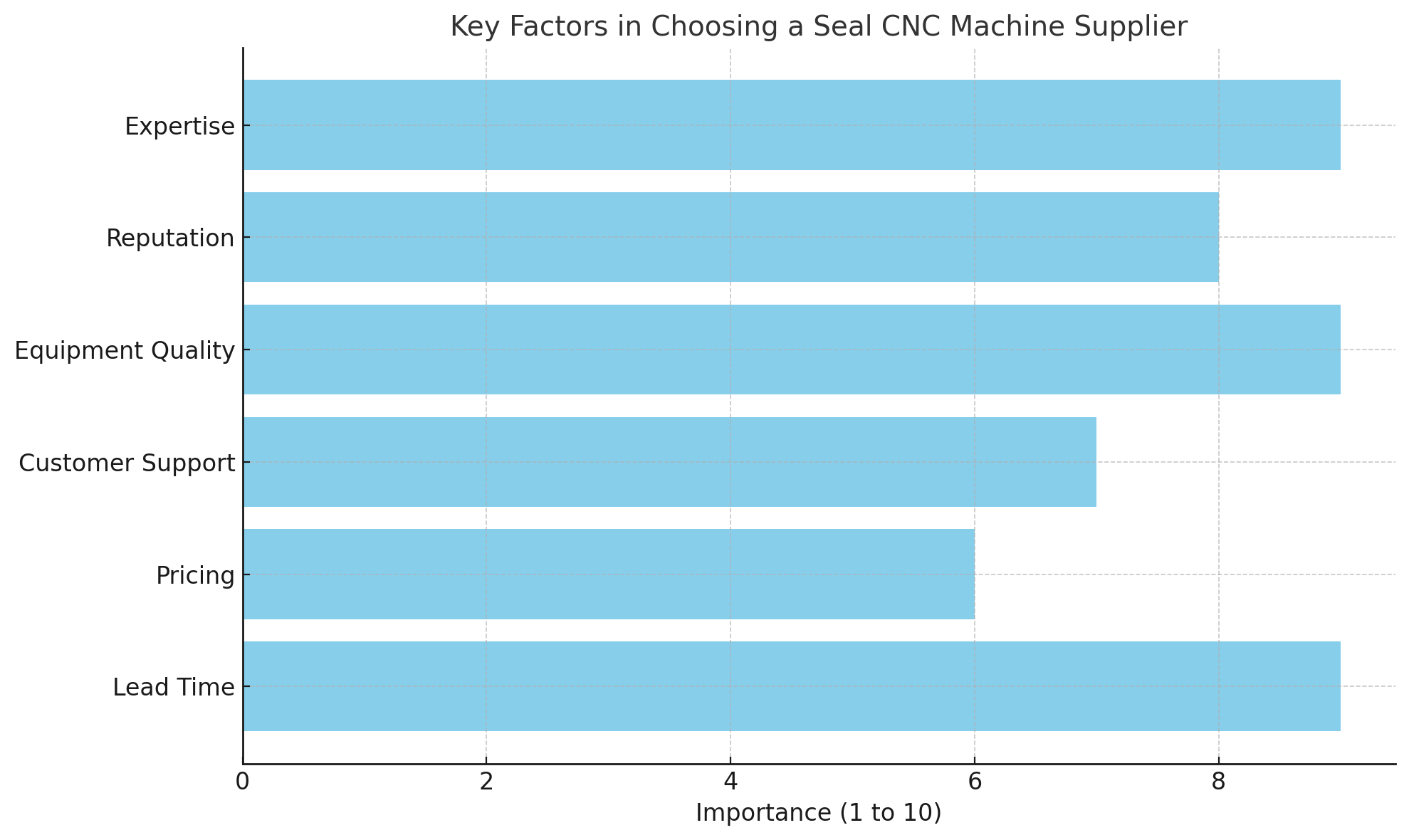

| Criteria | Importance | Example Considerations |

| Expertise | High | Experience in seal CNC machines, advanced capabilities, customization. |

| Reputation | High | Customer testimonials, case studies, industry reputation. |

| Equipment Quality | High | Modern CNC technology, precision, flexibility. |

| Customer Support | Medium | Timely responses, after-sales support, troubleshooting. |

| Pricing | Medium | Transparent pricing, value for money, long-term relationship potential. |

| Lead Time | High | Ability to meet deadlines, handle rush orders, flexibility. |

How to Assess the Supplier's Reputation and Reliability

Look for Customer Testimonials and Case Studies

The reputation of your potential CNC machine supplier is crucial. Testimonials and case studies can provide insight into the supplier’s ability to meet deadlines, provide quality products, and support customers through the production process.

Why It Matters:

● Testimonials offer real-world feedback, confirming the supplier’s reliability and the quality of the seals they produce.

● Case studies show how the supplier has handled various challenges and provided solutions for similar businesses.

Review the Supplier's Certifications and Quality Assurance Processes

A reputable supplier will have relevant industry certifications, such as ISO 9001, ensuring that their manufacturing processes meet global standards. Their commitment to quality assurance will also be evident through thorough inspection processes and consistent testing.

Why It Matters:

● Certifications and robust quality assurance processes demonstrate a supplier’s dedication to high standards and continuous improvement.

● Seal CNC machine suppliers with quality certifications are more likely to deliver consistent, high-performance products.

Supplier’s Delivery Track Record

Timely delivery is a critical aspect of a CNC machine supplier's reliability. Delays in seal production can disrupt your operations, so it’s essential to choose a supplier with a proven track record of meeting delivery deadlines.

Why It Matters:

● A reliable supplier will ensure your seals are produced and delivered on time, minimizing any disruptions to your production schedule.

● Fast delivery times also allow you to quickly respond to changing demands or urgent projects.

Consider Cost and Value for Money

Get Detailed Pricing Information

While cost is always a consideration, the cheapest option may not always provide the best value. Ensure you understand the full pricing structure, including any hidden costs associated with shipping, tooling, or customization.

Why It Matters:

● Transparent pricing ensures you are getting a fair deal for the quality and services provided.

● Seal CNC machine suppliers that offer clear, itemized pricing help you avoid surprises down the line and ensure you're investing in the right solution.

Evaluate the Supplier's Ability to Scale

As your business grows, so will your need for seals. Choose a supplier that has the capacity to handle both small batches and large-scale production runs, and is capable of scaling up production when needed.

Why It Matters:

● A scalable supplier can handle fluctuations in order size, ensuring that your seal production is always in line with demand.

● Seal making CNC machines that can accommodate larger runs without sacrificing quality will support your long-term business growth.

Communication and Customer Support

Importance of Clear and Timely Communication

A CNC machine supplier should have an efficient communication system in place. You should be able to easily contact the supplier, get updates on production, and resolve issues quickly.

Why It Matters:

● Clear communication reduces the likelihood of errors and delays, ensuring smooth project management.

● A supplier who is responsive and provides timely updates helps you stay informed and in control of the process.

After-Sales Support and Technical Assistance

After-sales support is an often-overlooked yet crucial aspect of a reliable supplier relationship. Your supplier should be available to offer troubleshooting, maintenance, and technical support as needed.

Why It Matters:

● Ongoing support helps address any operational issues that may arise with the seal CNC machines.

● A supplier who offers after-sales support ensures that your CNC machine and seals continue to perform at their best throughout their lifecycle.

The Role of CNC Technology in Seal Production

How Advanced CNC Machines Improve Seal Making

Advanced seal CNC machines provide several advantages, including improved precision, faster production speeds, and the ability to create complex, high-performance seals. These machines often incorporate automation, reducing human error and increasing overall efficiency.

Why It Matters:

● CNC technology plays a vital role in making seals more reliable and effective for high-pressure systems.

● Automation and software integration ensure consistent quality and precise control over the manufacturing process.

Customization and Tailored Solutions with CNC Machines

One of the key benefits of seal making CNC machines is their ability to produce highly customized seals. These machines can create seals in various materials, sizes, and shapes to meet specific application requirements.

Why It Matters:

● Custom seals are essential for applications where standard seals do not meet performance or durability standards.

● The ability to tailor seal designs ensures optimal fit and function in critical systems.

Supplier Location and Logistics

How Location Impacts Delivery and Costs

The location of your CNC machine supplier plays a crucial role in delivery times and costs. Domestic suppliers may offer quicker delivery and lower shipping costs, while international suppliers might provide more cost-effective options but with longer lead times.

Why It Matters:

● Consider the supplier’s location when evaluating shipping costs, delivery times, and potential communication challenges.

● The closer the supplier is to your facility, the faster the turnaround and delivery of the seal CNC machine.

Evaluate Logistics and Supply Chain Management

Effective logistics and supply chain management are essential for ensuring timely and cost-effective delivery of CNC-machined seals. Suppliers with strong logistics systems can offer consistent service and quickly address any unexpected delays.

Why It Matters:

● A well-organized supply chain reduces the risk of delays and helps manage inventory more effectively.

● Reliable logistics ensure that your seal production runs smoothly without supply interruptions.

Conclusion

Choosing the right seal CNC machine supplier is critical for achieving high-quality seal production. Factors like expertise, reputation, and equipment quality should be considered. A reliable supplier offers more than just cost savings; they provide long-term value through consistent performance and exceptional customer service. For businesses looking for top-quality CNC machines, BETA provides reliable solutions that can scale with your production needs, ensuring both precision and efficiency.

FAQ

Q: What factors should I consider when choosing a seal CNC machine supplier?

A: When selecting a seal CNC machine supplier, consider their expertise, reputation, equipment quality, customer support, and pricing. Reliability and performance should be key factors.

Q: How does a seal CNC machine supplier impact production quality?

A: A reliable seal CNC machine supplier ensures precision, high-quality seal production, and consistent performance, leading to reduced defects and improved product reliability.

Q: Why is customer support important when choosing a seal CNC machine supplier?

A: Strong customer support ensures that any issues with the CNC machines, such as troubleshooting or maintenance, are quickly addressed, minimizing downtime and keeping production on track.

Q: How do I assess the equipment quality of a seal CNC machine supplier?

A: Evaluate the supplier’s machine technology, capabilities, and maintenance standards. Advanced, well-maintained equipment results in more efficient and precise seal production.

Q: Can a seal CNC machine supplier handle both small and large orders?

A: A reliable seal CNC machine supplier should be able to scale their production capabilities to accommodate varying order sizes, ensuring flexibility in meeting your business needs.