Introduction

Hydraulic seals are vital to keeping machinery running smoothly by preventing fluid leaks and maintaining pressure. But what are they made of? And why does material selection matter so much?

In this article, we will explore the materials used in hydraulic seals and their impact on system performance. You'll also discover how seal cnc machines are transforming the way seals are produced, offering precision and customization.

What Are Hydraulic Seals?

Definition of Hydraulic Seals

Hydraulic seals are mechanical components designed to prevent the leakage of hydraulic fluid between parts in hydraulic systems. These seals are essential for maintaining fluid pressure and protecting the system's integrity. Typically, they are used in applications such as cylinders, pumps, and valves where fluid must be kept confined.

Basic Functionality and Design

The primary function of a hydraulic seal is to block the passage of fluid between components, maintaining the pressure needed to operate machinery. They are designed to fit precisely into grooves and are made to withstand varying pressures, temperatures, and harsh environments. Their ability to ensure tight sealing is key to preventing leaks and ensuring efficient system performance.

Common Materials Used in Hydraulic Seals

Rubber Seals

Rubber is one of the most common materials used in hydraulic seals. It is highly flexible and resilient, making it ideal for low-pressure systems. Rubber seals can withstand a wide range of operating conditions, including exposure to hydraulic oils and mild temperature variations. Their flexibility allows them to provide a tight seal even under pressure.

Benefits of Rubber Seals:

● Excellent sealing performance at low pressures

● High flexibility and elasticity

● Cost-effective for basic sealing needs

Polyurethane Seals

Polyurethane is increasingly used in hydraulic seals due to its superior abrasion resistance and strength. It can withstand high pressures and extreme temperatures, making it suitable for heavy-duty applications. Polyurethane seals also offer excellent chemical resistance, making them ideal for systems exposed to harsh environments.

Advantages of Polyurethane Seals:

● Outstanding wear and abrasion resistance

● Ideal for high-pressure and high-temperature environments

● Long-lasting and durable

PTFE (Polytetrafluoroethylene) Seals

PTFE is known for its excellent chemical resistance and high-temperature tolerance. PTFE seals are often used in systems that are exposed to aggressive fluids or extreme temperatures. These seals offer superior performance in challenging conditions and are commonly used in aerospace, automotive, and chemical processing industries.

Key Features of PTFE Seals:

● High resistance to chemicals and high temperatures

● Low friction, enhancing system efficiency

● Suitable for extreme operating conditions

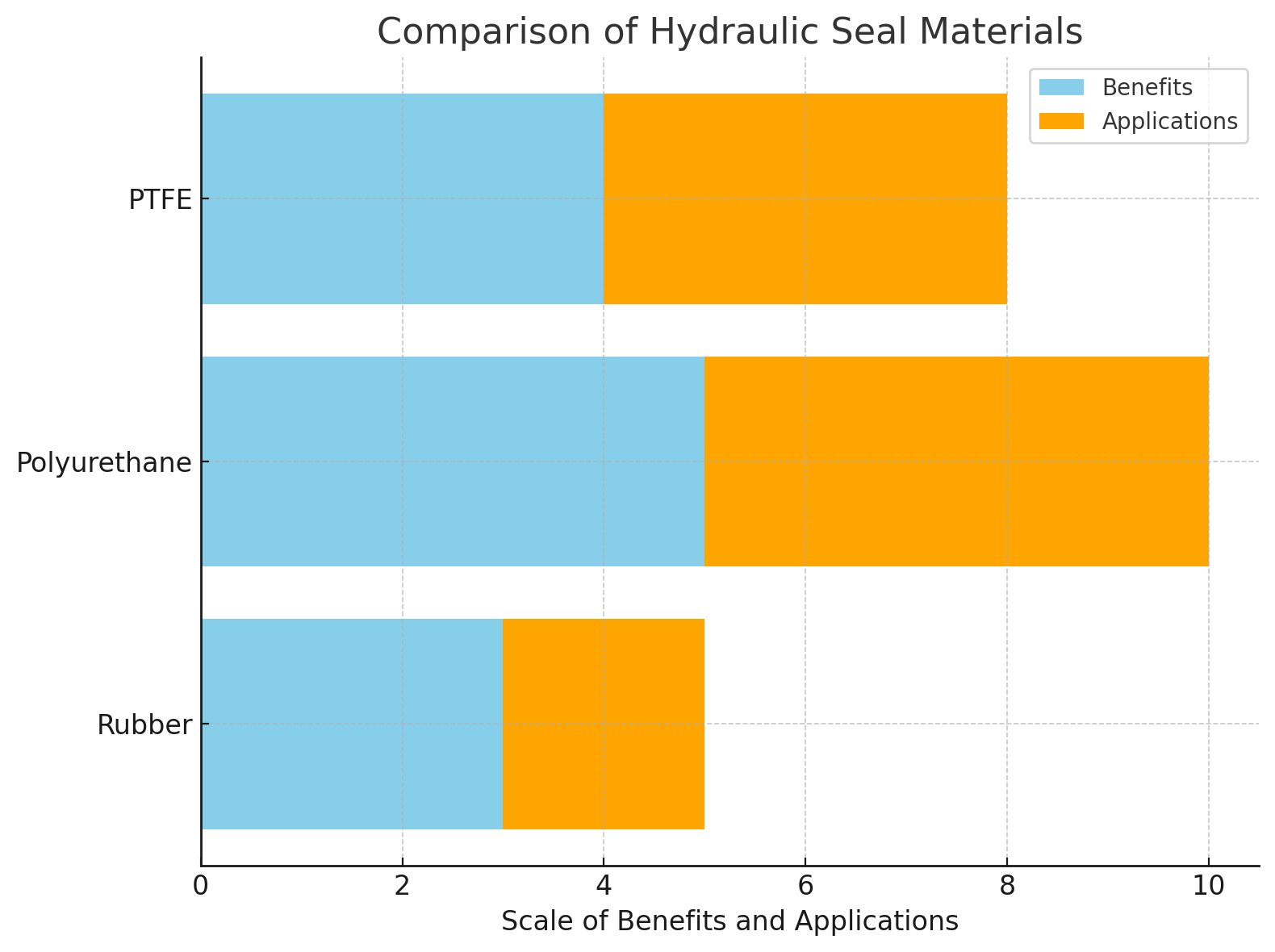

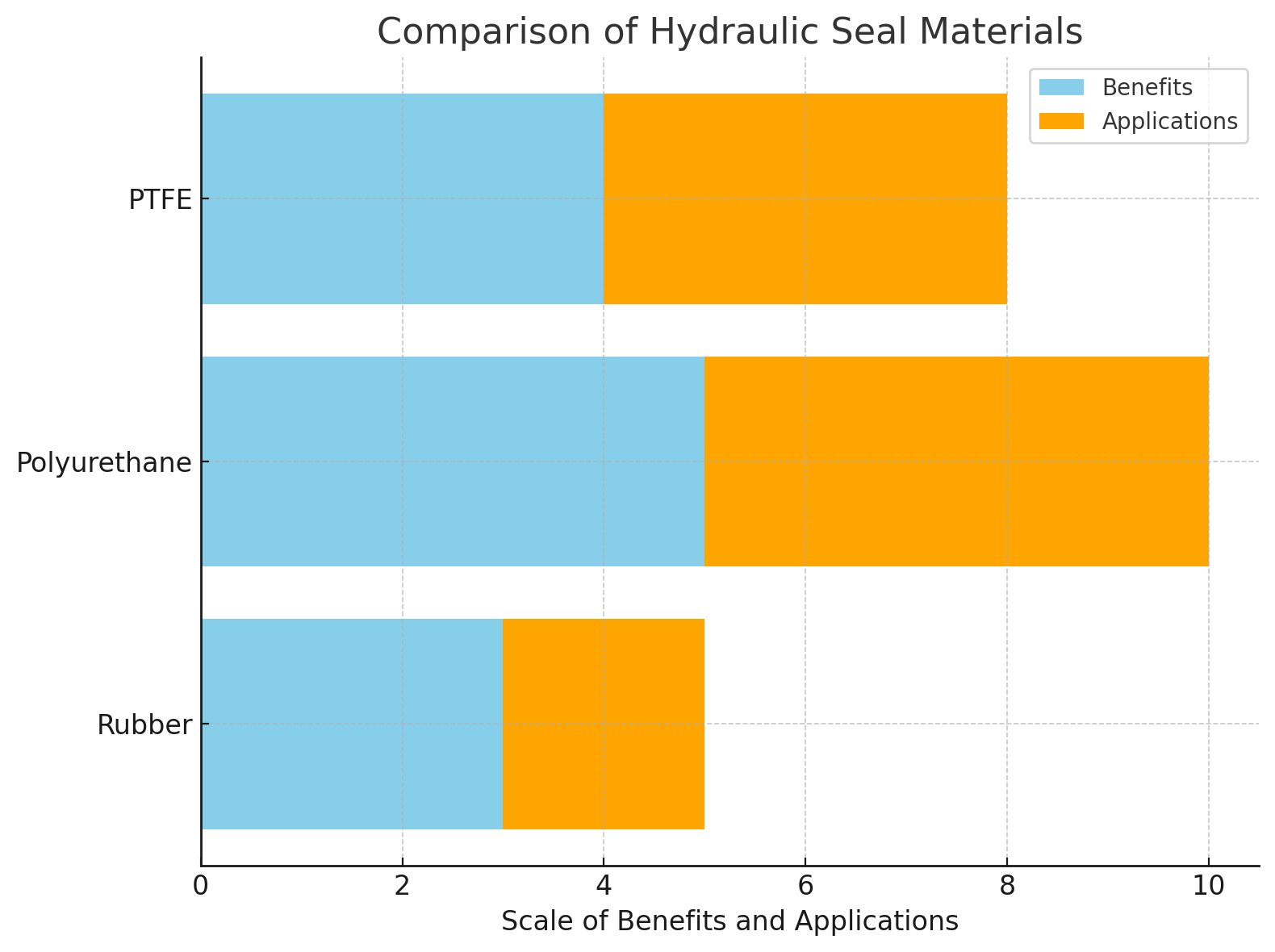

| Material | Benefits | Applications |

| Rubber | Flexible, durable, resistant to abrasion | Low-pressure systems, general industrial use |

| Polyurethane | High abrasion resistance, excellent chemical resistance, high-pressure tolerance | High-pressure systems, construction equipment, automotive |

| PTFE | High-temperature resistance, chemically stable, non-reactive | Chemical processing, high-temperature environments |

Material Selection for Hydraulic Seals

Factors Influencing Material Choice

When selecting the right material for hydraulic seals, it is essential to consider several factors:

● Pressure: High-pressure systems require seals made from materials like polyurethane or PTFE, which can withstand intense force.

● Temperature: Seals must be capable of handling both low and high temperatures without degrading. Materials like PTFE and rubber offer a range of temperature tolerances.

● Chemical Compatibility: Different materials interact with hydraulic fluids, and selecting a material that resists the specific chemicals in your system is crucial for seal longevity.

Matching Seal Material to Application

Each hydraulic system has unique demands based on its specific use case. For instance, seals used in automotive systems might require rubber seals for cost-effectiveness, while those in aerospace applications might need PTFE seals for high-temperature and high-pressure environments. Customization of seals is increasingly supported by technologies like hydraulic seal CNC machines, which can tailor seals to specific application needs.

Hydraulic Seal CNC Machines and Customization

Role of CNC Machines in Hydraulic Seal Manufacturing

CNC (Computer Numerical Control) machines have revolutionized the way hydraulic seals are produced. These machines allow manufacturers to create precise, custom seals that meet the exact specifications of hydraulic systems. CNC technology can work with various materials, including rubber, polyurethane, and PTFE, ensuring that seals are tailored for performance and durability.

Advantages of CNC in Seal Manufacturing

Using CNC machines for hydraulic seal manufacturing offers numerous benefits:

● Precision: CNC machines can create seals with high precision, ensuring that the seals fit perfectly in their respective grooves and perform optimally.

● Consistency: CNC machines can produce identical seals at a high volume, reducing variability and ensuring consistent quality.

● Speed: CNC machines can quickly produce seals, reducing lead times for custom orders and allowing manufacturers to meet tight production schedules.

How CNC Machines Enhance Material Performance

The use of CNC machines enhances the performance of hydraulic seals by allowing for custom designs that optimize material properties. For example, CNC machines can create seals with specific lip profiles or surface finishes that reduce friction and extend seal life. This level of customization is particularly beneficial when working with advanced materials like PTFE or polyurethane.

The Durability and Performance of Hydraulic Seal Materials

Comparing Material Durability

Different materials used for hydraulic seals offer varying levels of durability and performance:

● Rubber: Offers good flexibility but can degrade over time due to wear and exposure to harsh chemicals.

● Polyurethane: More drable than rubber, it provides superior abrasion resistance and can handle high-pressure and high-temperature environments.

● PTFE: Known for its excellent chemical resistance and high-temperature tolerance, PTFE seals perform well in extreme conditions.

Cost vs. Performance Trade-Off

Choosing the right material for hydraulic seals is often a balance between cost and performance. While rubber seals are cost-effective, they might not perform well in high-pressure or chemically aggressive environments. Polyurethane and PTFE seals, although more expensive, offer superior durability and are better suited for challenging applications.

Specialized Seals for High-Pressure Applications

Materials for Extreme Conditions

For systems exposed to extreme pressures, high temperatures, or corrosive chemicals, specialized materials like polyurethane and PTFE are essential. These materials offer the necessary strength and resistance to ensure seal integrity in demanding environments.

Case Studies: Hydraulic Systems Using High-Pressure Seals

Real-world examples highlight how specialized seals perform under extreme conditions:

● Hydraulic presses: Using PTFE seals ensures minimal leakage and maintains consistent performance at high pressures.

● Construction equipment: Polyurethane seals in hydraulic cylinders improve equipment reliability and reduce maintenance downtime by withstanding harsh conditions.

Challenges in Hydraulic Seal Material Selection

Material Failures and Common Issues

Selecting the wrong material can lead to seal failure, resulting in fluid leaks, system downtime, and potential damage to machinery. Common issues include:

● Premature wear: Seals made from rubber or low-grade materials may wear out quickly.

● Chemical incompatibility: Incorrect material selection can lead to seal degradation when exposed to specific fluids.

Impact of Environmental Conditions

Environmental factors, such as temperature fluctuations, chemical exposure, and mechanical stress, can significantly impact seal performance. Regular maintenance and proper material selection are essential to ensure seals continue to function effectively over time.

Conclusion

Hydraulic seals are critical for the performance and safety of hydraulic systems. The right material—rubber, polyurethane, or PTFE—ensures optimal performance across various applications. CNC technology has revolutionized seal production by providing precision and customization, improving seal durability. Factors like pressure, temperature, and fluid compatibility play a key role in material selection. Using CNC machines allows manufacturers to create tailored seals for specific systems, ensuring long-lasting, reliable performance. BETA offers high-quality hydraulic seal solutions, leveraging advanced CNC technology to meet precise system requirements and enhance performance.

FAQ

Q: What materials are hydraulic seals made of?

A: Hydraulic seals are commonly made of rubber, polyurethane, and PTFE. Each material offers specific benefits, such as flexibility, chemical resistance, and high-pressure tolerance.

Q: How do CNC machines improve hydraulic seal production?

A: CNC machines enable precise, custom manufacturing of hydraulic seals, ensuring better performance and longer lifespan. This technology allows for exact material configurations, enhancing overall efficiency.

Q: Why is selecting the right material crucial for hydraulic seals?

A: The right material ensures optimal sealing performance under varying pressures, temperatures, and fluid types, directly impacting system reliability and longevity.

Q: Can hydraulic seal CNC machines handle different materials?

A: Yes, CNC machines are versatile and can manufacture seals from various materials, including rubber, polyurethane, and PTFE, ensuring high precision in each product.

Q: How do hydraulic seal CNC machines contribute to customization?

A: CNC technology allows for highly customized hydraulic seals, enabling manufacturers to meet specific system requirements and improve sealing performance.

Q: What is the advantage of using CNC technology for hydraulic seals?

A: CNC technology provides unparalleled precision, speed, and consistency in seal production, improving the reliability and durability of hydraulic systems.