Introduction

Polyurethane (PU) seals are essential for reliable performance in many industries, from hydraulics to aerospace. But how well do they perform in extreme temperatures?

In this article, we’ll explore the temperature range of PU seals, why it matters, and how selecting the right material ensures longevity and efficiency. You'll learn about the role of CNC technology in improving seal performance across various conditions.

Understanding the Basics of PU Seals

What Are Polyurethane Seals?

Polyurethane seals are made from a flexible and durable polymer known for its strength and resistance to wear, making it ideal for sealing applications. These seals are used in multiple industries, including automotive, aerospace, and manufacturing, where they provide long-lasting, leak-free operation.

Why PU Seals Are Preferred in Extreme Conditions

PU seals offer superior benefits over alternatives like rubber and PTFE due to their flexibility, high abrasion resistance, and remarkable temperature tolerance. These properties allow PU seals to perform reliably in extreme conditions such as high-pressure and temperature environments.

Temperature Range of PU Seals

General Temperature Limits for PU Seals

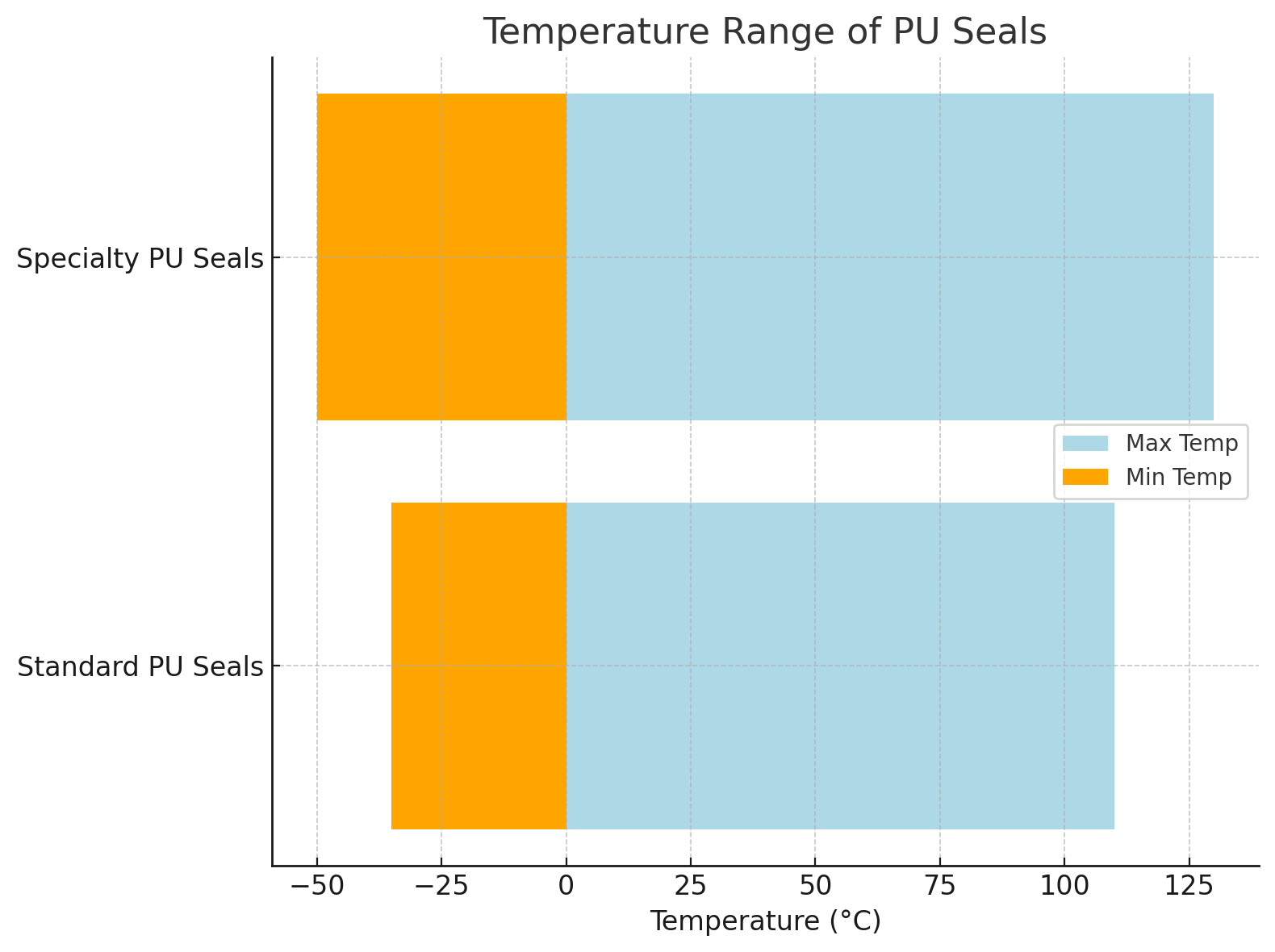

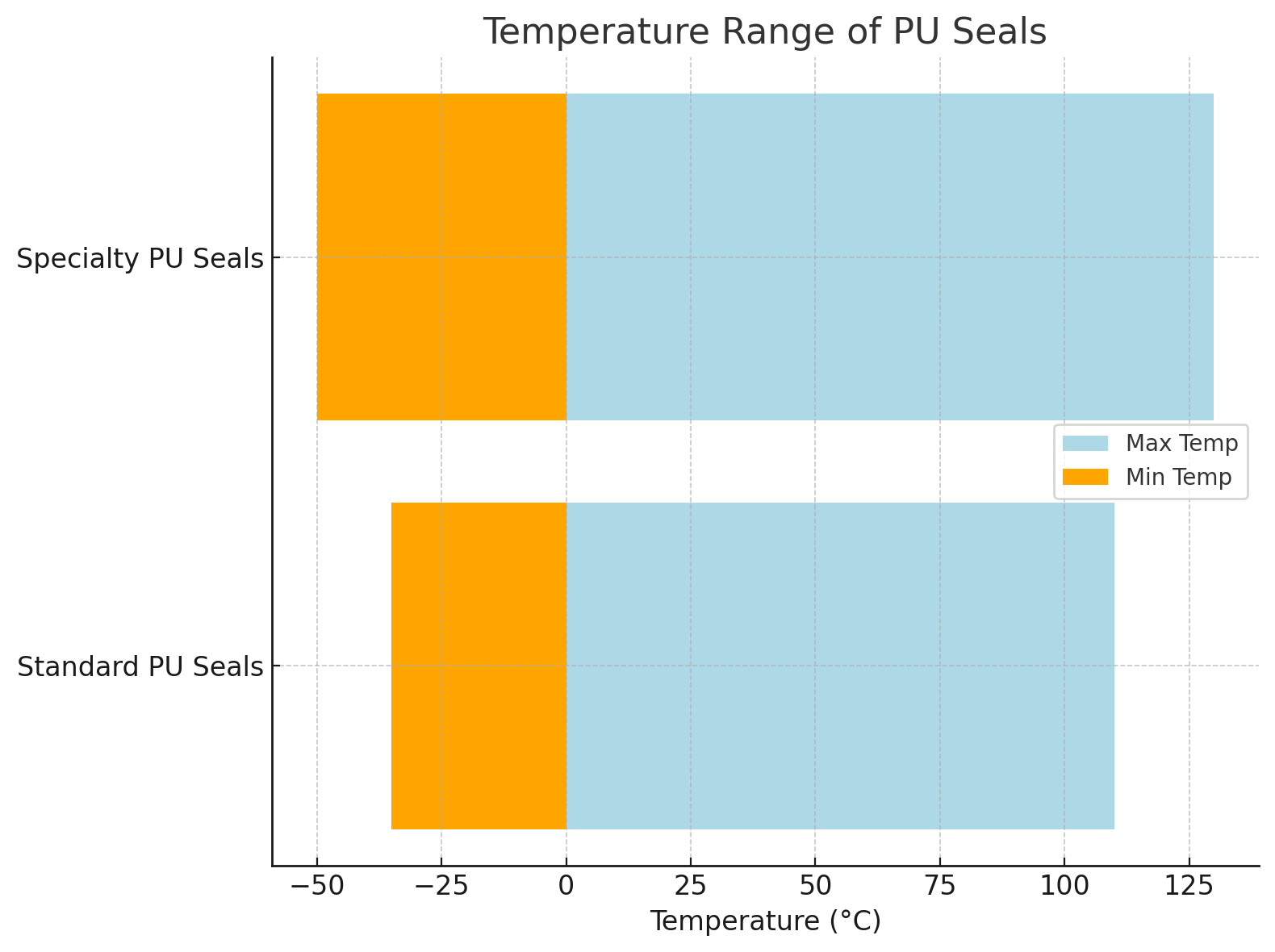

Polyurethane seals typically have a general operating temperature range of -35°C to +110°C. This range makes them suitable for a variety of applications, from everyday machinery to specialized systems. Some specially formulated PU seals can extend their flexibility down to -50°C and can operate up to +130°C, depending on the grade.

Why Different PU Grades Have Varying Temperature Ranges

Different formulations of PU, including various additives and curing processes, influence their temperature resistance. For instance, seals designed for high-temperature applications will have additives that help them maintain flexibility and durability under extreme heat, while others are specifically designed for low-temperature environments.

PU Seal Type | Temperature Range | Applications | Manufacturing Process |

Standard PU Seals | -35°C to +110°C | General industrial, hydraulic, pneumatic systems | CNC machining for precise seals |

Specialty PU Seals | -50°C to +130°C | High/low-temperature industrial systems | Seal CNC machine for tailored production |

Factors Affecting the Temperature Tolerance of PU Seals

Material Composition

Polyurethane seals are created through a process involving polyols, isocyanates, and chain extenders. The chemical composition of these ingredients plays a significant role in determining the thermal properties of the final product. Higher-quality materials and precise mixing can extend the seal’s temperature range.

Manufacturing Process

The temperature resistance of PU seals is enhanced by advanced manufacturing techniques like CNC machining. CNC lathes provide precise cutting and shaping, ensuring that the seals meet exact specifications, which directly impacts their performance in extreme temperatures. The control over the manufacturing process enables the creation of seals with optimized properties for both high and low-temperature applications.

Environmental Conditions

While the material itself plays a role in temperature resistance, external factors like humidity, pressure, and exposure to chemicals can affect how PU seals perform under extreme temperatures. For example, exposure to high-pressure environments can reduce a seal's ability to function in colder temperatures.

High-Temperature Applications for PU Seals

Industries That Rely on PU Seals in High-Temperature Environments

Industries such as automotive, aerospace, and heavy machinery often rely on PU seals in systems that are exposed to high temperatures. In automotive engines or hydraulic systems, PU seals must withstand high operating temperatures without degrading or losing their sealing properties.

Performance and Durability in Extreme Heat

PU seals maintain their strength and elasticity at elevated temperatures. This ability makes them suitable for high-performance applications, such as hydraulic pumps, compressors, and other machinery components that experience sustained high heat.

Low-Temperature Performance of PU Seals

Challenges of Low Temperatures on PU Seals

When exposed to low temperatures, PU seals face the risk of becoming brittle, losing flexibility, and eventually cracking. These challenges are more pronounced in systems that operate at freezing temperatures or in cold climates.

PU Seal Performance in Cold Environments

Special grades of PU seals are designed to handle colder environments, maintaining their flexibility and strength as low as -50°C. These seals are crucial in industries like refrigeration and cold storage, where temperature extremes are part of daily operations.

Impact of Temperature on Seal Longevity and Performance

How Temperature Affects Seal Life

Prolonged exposure to temperatures outside the seal’s rated range can lead to faster degradation, cracking, and overall reduced service life. Seals operating in high-temperature environments may soften, while those in extreme cold may become rigid and lose their sealing properties.

Cost of Overheating or Overcooling a Seal

Using a seal that cannot handle the operating temperature range can lead to system failures, increased downtime, and higher maintenance costs. Selecting the correct seal material is essential for minimizing long-term costs associated with seal breakdowns.

How CNC Technology Improves PU Seal Temperature Resistance

CNC Machining and Seal Customization

CNC machines are crucial in producing precise, custom seals designed to withstand specific temperature ranges. CNC technology allows for the exact shaping of PU seals, ensuring that they perform optimally in high- or low-temperature environments.

The Role of CNC in Temperature-Specific Seal Production

By using CNC technology, manufacturers can create PU seals that are tailored to meet the exact needs of an application, whether it's high heat tolerance for automotive parts or low-temperature flexibility for cold storage systems.

Conclusion

PU seals offer versatile temperature ranges, typically from -35°C to +110°C, with special grades extending to -50°C or +130°C. Their durability in extreme temperatures makes them ideal for various industries.

When choosing a PU seal, consider temperature needs, fluid compatibility, and environmental factors. The right PU seal ensures optimal performance in both high and low-temperature conditions.

CNC technology is essential in producing precise PU seals that meet specific temperature demands. This guarantees long-lasting, reliable performance for demanding applications. BETA offers CNC solutions tailored to meet these exact requirements.

FAQ

Q: What is the typical temperature range for PU seals?

A: The typical operating temperature range for PU seals is between -35°C and +110°C. Some special grades can handle temperatures as low as -50°C or as high as +130°C.

Q: Why does temperature matter when choosing a PU seal?

A: Temperature affects a seal’s performance. Using a PU seal outside its specified temperature range can lead to seal failure, reduced lifespan, and inefficiency.

Q: How does CNC technology help in producing temperature-resistant PU seals?

A: CNC machines are used to precisely manufacture PU seals. This ensures that the seals meet exact temperature tolerance requirements for demanding applications, including high-pressure systems.

Q: Can PU seals be customized for specific temperature requirements?

A: Yes, CNC technology allows for the production of highly customized PU seals. Manufacturers can adjust properties to meet temperature-specific demands, ensuring optimal performance.

Q: How does the manufacturing process affect the temperature tolerance of PU seals?

A: The materials and additives used during the manufacturing process, such as polyols and isocyanates, directly influence a PU seal's temperature tolerance. CNC machining ensures precise temperature-resistant properties.

Q: Are PU seals better than other materials for extreme temperatures?

A: Yes, PU seals outperform many other materials, such as rubber or PTFE, in extreme temperatures due to their superior wear resistance, elasticity, and temperature tolerance.

Q: What industries benefit from using PU seals in extreme temperatures?

A: PU seals are widely used in industries like automotive, aerospace, and manufacturing, where high or low temperatures are a concern. CNC technology ensures the seals perform reliably in these applications.